http://www.pipe-cn.com

Brief Introduction: Ningbo Sanding Steel Pipe Company is located in Ningbo Economic and Technological Development Zone, Zhejiang Province, China. It is a professional production enterprise engaged in super long and super large diameter welded steel pipe. Has 5000 tons of gantry file type self-provided wharf. The company takes large and medium diameter spiral seam buried arc welded steel pipe and straight seam pipe as the main products, and has the largest spiral welded pipe unit in China, which can realize mobile production. The annual production capacity is 200,000 tons, the pipe diameter is Ф 400~3050mm, and the wall thickness is δ 5~25mm.

EZW11XY-150*3500 three-roll plate rolling machine

(EZW11XY-150 * 3500, a three roller bending machine)

order number | item | unit | data | |

1 | Machine specifications | mm | 150×3500(245Mpa) | |

2 | The upper roller diameter | mm | 1060 | |

3 | Lower roller diameter | mm | 860 | |

4 | Upper and lower roller material | 60CrMnMo 42CrMo | ||

5 | Straight edge coefficient | mm | 2~2.5times the plate thickness | |

6 | Circulating temperature | C | 20°C Cold roll | |

7 | Plate yield limit | MPa | 245 | 360 |

8 | The maximum width of the coil | mm | 3500 | 3500 |

9 | Minimum drum diameter at full load | mm | Φ3000mm | Φ3500mm |

10 | maximum thickness of bending plate | mm | 150 | 125 |

11 | Prebend plate thick | mm | 130 | 100 |

12 | Two lower roll center distance | mm | 1050~1750 | |

13 | Effective length of the working roller | mm | 3580 | |

14 | Upper roller drives the total torque | t.m | 120 | |

15 | Lower roller drive total torque | t.m | 2*3.5 | |

16 | Horizontal movement speed of the lower roller cylinder | mm/min | 350 | |

17 | Hydraulic system pressure and flow rate | Mpa | Motor~17, other up to 25 | |

18 | Pressure the cylinder diameter | mm | Ф870/Ф370/630 | |

19 | Total pressure under force | t | 2430 | |

20 | Horizontal push for cylinder diameter | mm | Ф480 | |

21 | horizontal thrust | ton | 900 | |

21 | upper roll speed | mm/min | 0~200 | |

23 | The power of the machine | Kw | ≈300 | |

24 | Horizontal movement of the lower roll on each side | mm | 0~650 | |

https://www.cssc.com.cn

Introduction: Jiangyou Great Wall Special Steel Co., LTD. (hereinafter referred to as: Great Wall Special Steel) is located in the hometown of —— Shixian Li Bai, Jiangyou City, Sichuan Province, with beautiful scenery, pleasant climate and convenient transportation. Founded in 1965, the company is a national special steel research and production base and a large backbone enterprise in Sichuan Province. It is an overall solution provider of high-end metal materials in China. It has an annual production capacity of 500,000 tons of special steel and 700,000 tons of special steel.Product coverage is wide, the company can be in accordance with the national standard, international standards and user technical conditions, provide carbon steel, steel, bearing steel, spring steel, mold steel, stainless steel, high strength steel, high temperature alloy, corrosion resistant alloy, precision alloy, titanium and titanium alloy and other 13 categories, more than 400 brand of special steel, special alloy and titanium products. The products are widely used in aviation, aerospace, Marine assembly, nuclear power, transportation, machinery, petrochemical and other fields, among which special alloy, special stainless steel, mold steel and other products occupy an important position in China, and the market share ranks among the best in the same industry.

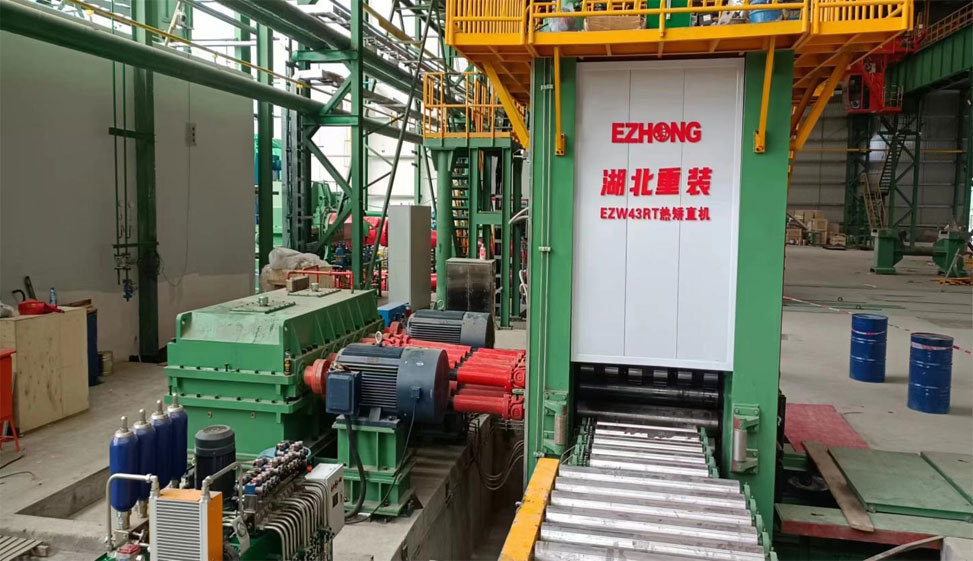

EZW43BY-25*1500 11 rolls 1200mpa

(EZW43BY-25*1500 11 rolls 1200mpa)

Serial number | Name | Model specification | ||||

1 | Straightening plate | Yield limit (MPa) | 900C (≤ 800C) | |||

Maximum thickness (mm) | 2-4 | 4. 6. | 6: 20 | 20: 25 | ||

Minimum thickness (mm) | 2mm | |||||

Maximum width (mm) | 1350mm | |||||

2 | Work roll | Roll distance (mm) | 250mm | |||

Roll diameter (mm) | 220mm | |||||

Roll length (mm) | 1450mm | |||||

Number of rolls | 11 (upper 5 and lower 6) | |||||

3 | Supporting roll | Roll distance (mm) | 250mm | |||

Roll diameter (mm) | 235mm | |||||

Number of columns | 3 | |||||

4 | Movable beam | Press-down stroke (mm) | + 100~-17mm | |||

Press-down speed (mm/min) | 25mm/min | |||||

Maximum swing | ±5mm | |||||

Lifting height | 130mm | |||||

5 | Correction speed (m/min) | 3: 20 frequency conversion is reversible, 10 at full load | ||||

6 | Correction accuracy (mm/ accuracy) | ≤ 10 | ≤ 5 | ≤ 3 | ≤ 10 | |

7 | Main motor power | 110KW × 2 | ||||

8 | Press-down motor power | 5.5KW × 2 | ||||

9 | Correct the relative elevation of the roll surface | 800mm | ||||

10 | The external dimensions of the mainframe (length × width × height) | ~ (7100 × 5562 × 5446) | ||||