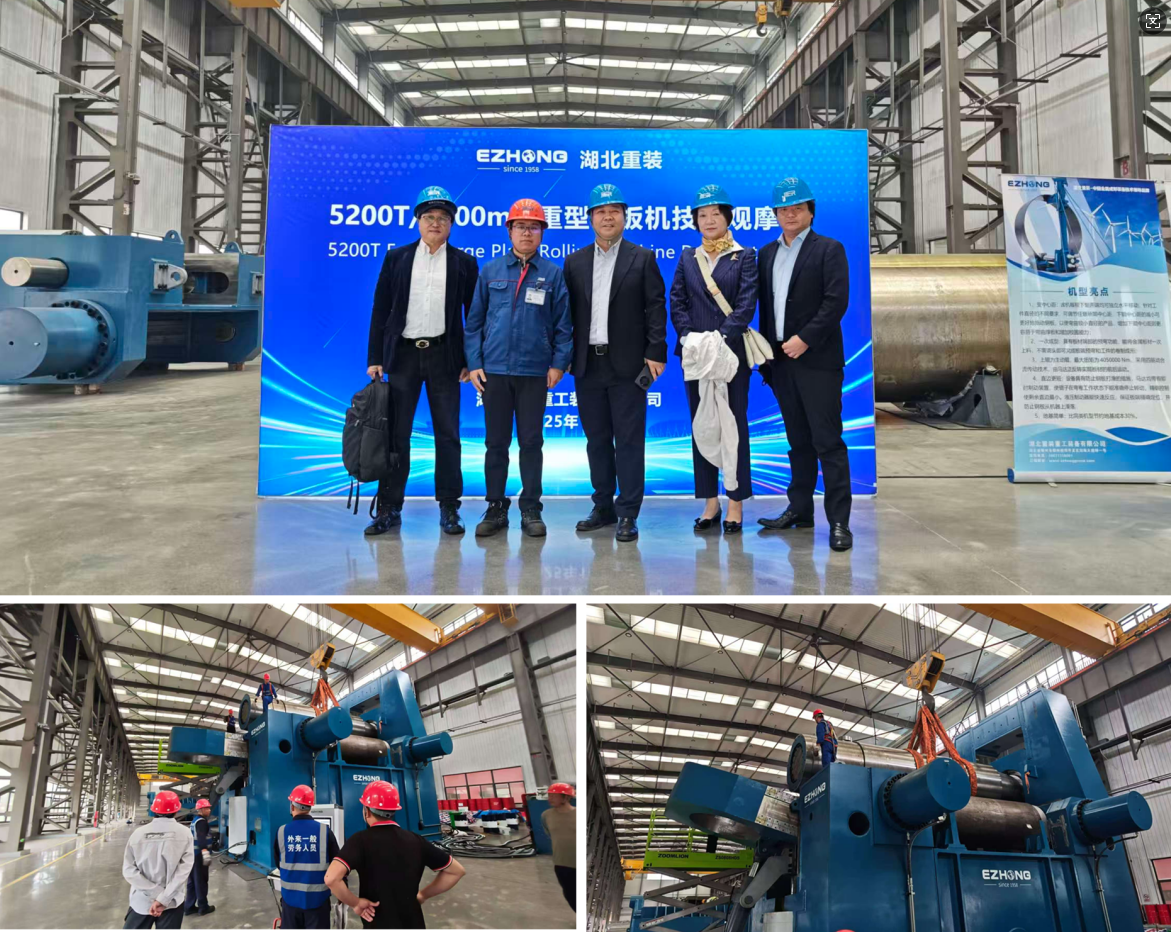

EZHONG wind tower special CNC change geometric level deconditioned 3 roll bending machine is a domestic and foreign wind tower manufacturer's best-selling machine, high roll accuracy, which is a large-scale roll panel equipment in China.

The wind tower bending machine is equipped with bracket support, conveying platform.

High efficiency, the steel plate can be rolled into a cylinder within 30 minutes.

The steel plate bender is equipped with a national-style console and a remote control button box, which is convenient for workers to work efficiently.

The steel plate bender is equipped with safety interlocking device to make the operation safer.

Simple operation, convenient maintenance, high rolling precision.

Our effective solutions for your windmill production

1、Variable Center Distance: Each end of every lower roll of this machine can move horizontally independently.

According to different requirements for workpiece diameters, any required center distance can be adjusted.

Reducing the center distance between lower rolls enables better traction of steel plates, facilitating the bending

of small-diameter products; increasing the center distance between lower rolls makes it easier to bend thick plates

and enhances roundness correction capability.

2、One-step Forming: It is equipped with a plate end pre-bending function. A metal plate can be loaded in one go,

and both plate end pre-bending and workpiece roll forming can be completed without turning the plate around.

3、The upper roll is the driving roll, with a maximum torque of 4,050,000 Nm. It adopts four-drive confluence transmission

technology, and the forward and backward movement of the plate is realized through the forward and reverse rotation of the motor.

4、Shorter Straight Edge: The equipment is equipped with anti-slip measures for steel plates. All motors are fitted with instant braking devices,

which allow the rolls to stop rotating accurately during the rolling process. Precise control minimizes the remaining straight edge. The

hydraulic brake can respond rapidly, ensuring precise positioning of the plate end and preventing the steel plate from slipping off the machine.

5、Simple Foundation: It saves 30% of the foundation cost compared with similar models.