Plate Bending Machine Working Principle

The purpose of the plate bending machine is to bend the plates with different characteristics according to the production capacity.

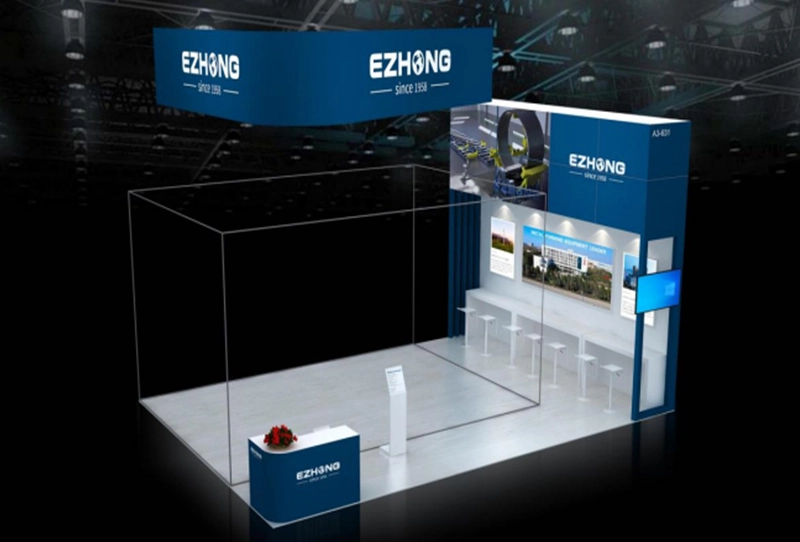

The production process of the plate bending machine in EZHONG is to operate the machine from the control panel (equipped with all control equipment and indicator lights) under the control of the operator.

The working cycle controlled by PLC (option) is adjusted by limit switches, position sensors and other display sensors. These adjustments ensure the accuracy of the work and eliminate the possibility of program errors. Through the interface on the control panel, several manual operations can be concentrated into simple guided actions.

The variable center distance hydraulic horizontal 3 roller pipe bending machine is a machine with medium/large thickness plate pre-bending and rolling products of different shapes.

This model is different from the traditional model, because each of its lower plate rollers can move independently horizontally to produce any desired pitch, and the upper plate rollers with motors can move vertically.

The possibility of increasing the distance between the lower plate rollers determines that the same force and power as multiple pre-bending machines can be used in only one machine. The controlled horizontal movement of the lower roll makes the pre-bending operation very easy. The reduction of the center distance of the lower steel plate rollers can better drag the steel plate, which facilitates the subsequent bending of products with smaller diameters and thickness, and facilitates the measurement of the curved plate that must be welded.

Increasing the center distance of the lower steel plate rollers makes it easier to bend thick plates and increases the rounding ability.

Due to the upper profiled roller operating system, the plate roll bending machine can be used as a traditional press to perform pressing and measure the finished product.

In the same way, very thick cone plates and curved plates can also be produced through different pressing operations.